10.4 Proactive Identification

As mentioned in the previous section, there are established methods that help detect, prioritise and treat high crash-risk sites based solely on prior crash history. Although these locations should be a target for funding and attention, they only comprise a small proportion of the network that is responsible for casualty crashes, especially in higher income countries. For example, SWOV (2010) reports that in the Netherlands during 1987–89, only 10.5% of all fatal and hospital in patient crashes occurred at high-risk locations. In the 1997-99 period, this had declined to 6%. For the period between 2006 and 2008, the figure was only 1.8%. This study concludes that an increasing number of serious crashes occur at locations that are not high-risk locations.

Proactive safety actions can be employed to avoid future crashes by:

- Ensuring the safest road design scheme is selected for construction.

- Checking that the proposed road infrastructure or feature is designed and built to minimise the occurrence of road safety problems.

- Treating safety issues on existing road networks before crashes occur at these locations.

Various types of proactive actions have long been included in the practices of road authorities, including:

- The conduct of impact studies or public inquiries during the development of road projects in order to assess their expected effects on safety, mobility, environment, operating costs, public acceptance, etc.

- Observations at selected sites using procedures and techniques that have been developed to assist in the detection of unsafe features, behaviour or manoeuvres.

- Road network inspections in order to detect hazardous elements. Since the 1960s, guides have been published to help in the identification of these features. (e.g. AASHO, 1967).

It should be noted that proactive actions, whilst being a preventative measure, should not be a simple check of compliance with design standards. Often the design can meet standards, but due to the configuration, or due to adoption of minimum standards on a number of road elements, the design may be unsafe.

This section will discuss several types of road safety checks that are generally performed at different stages of implementation of a road scheme. These checks may occur for a new road or road feature, modification to an existing road or feature, and even during the usual operation of a road.

Although the focus of this chapter is on identifying risks, and the tools used in this process, some of the approaches described also help in the identification of solutions or even in the prioritisation of interventions (both discussed in Chapter 11. Intervention Selection and Prioritisation). The content beyond the risk identification stage is also included in this chapter where relevant for completeness. Therefore, this material should be read alongside the following chapter on treatment selection and prioritisation.

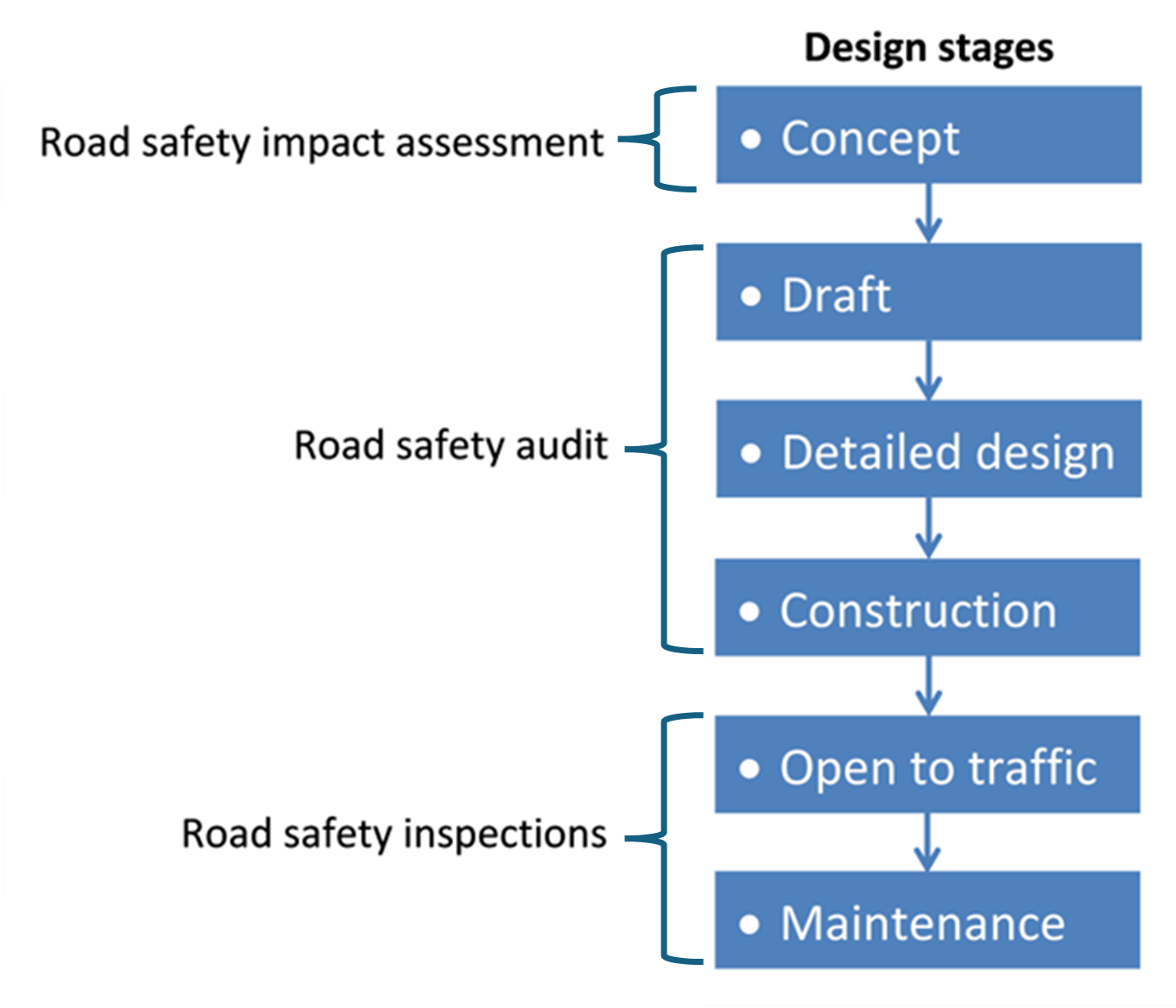

The road safety check types are:

- Road safety impact assessments – used to ensure the scheme is selected (out of a number of different schemes) that has the best outcome for road safety.

- Road safety audits – performed to check that the selected scheme is designed and constructed in such a way as to yield the greatest road safety benefits, and to detect any potential hazards throughout the design and construction.

- Road safety inspections – undertaken as part of an inspection of an existing road, or through maintenance procedures to enable the detection of potential crash risks.

- Road assessment programmes – typically undertaken on existing roads, these quantify the expected safety outcomes for a network, route or location.

It should be noted that safety inspection of existing roads is sometimes referred to as an audit of existing roads in some countries, but the terms refer to a similar process.

The aim of each of these road safety checks are similar, however, the main distinction is in the timing and scope of the procedures, as shown in Figure 10.18. Road assessment programmes are typically used to assess roads that are already in use, but recent developments have extended this to include assessment of road design.

Given the different timing and scope of each procedure, all can be undertaken in parallel. It is up to individual countries as to which procedures are adopted. Each has different advantages and weaknesses, and these are documented in the following sections.

Some of the main objectives and benefits of undertaking any of these road safety checks include (PIARC 2012a):

- The future minimisation of crash risk, severity and occurrence at the site and on adjacent roads.

- Recognising the importance of considering safety in road design.

- Reducing long-term operating/maintenance costs and the need for remedial work (through efficient and safe design selection).

- Bringing an increased awareness to road safety issues and solutions amongst policy-makers and scheme designers.

The different road safety check types are thoroughly outlined in a number of national guidelines, some of which are available internationally. Example guidelines are provided throughout the remainder of this chapter.

Other tools to assess safety at the planning and development stage are included in Section 9.4 Management Tools. Some of these tools are designed for use by practitioners with little or no road safety experience and are intended to identify and address risk at the earliest stages of project and programme development.

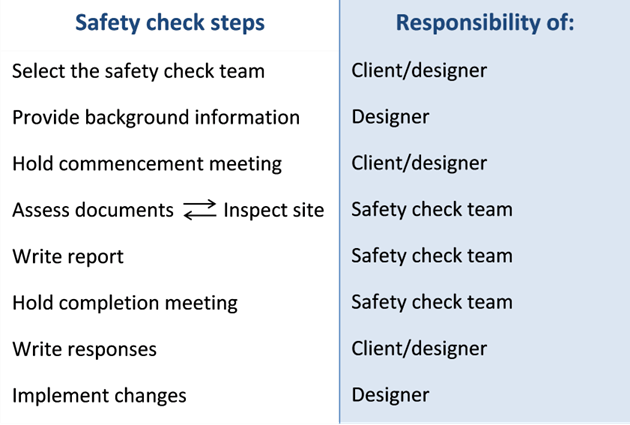

Road safety checks generally follow a similar managerial procedure. This is outlined in Figure 10.19, which also indicates who has responsibility for each stage of the process.

ROAD SAFETY IMPACT ASSESSMENT

Road safety impact assessment is conducted for infrastructure projects at the initial planning stage before the infrastructure project is approved. It indicates the road safety considerations which contribute to the selection of the proposed solution and provides all relevant information necessary for a cost-benefit analysis of the different options assessed. This allows a comparison of the impact of different road or traffic schemes on safety performance. These could be for a new road or for modification to an existing road. This is a procedure that should first be performed in the initial planning stage of a project to assist in the selection process for major infrastructure projects and should then be continually reviewed during the draft design phase. Safety impact assessment often precedes Road Safety Audit, but is done as a complementary process. As identified in Examples of Infrastructure Policies, Standards and Guidelines in Section 9.3 Policies, Standards and Guidelines, impact assessment is required for all infrastructure projects on the primary network as part of an EU Directive.

There are five main steps to a road safety impact assessment, as outlined by Eenink et al. (2008):

- Establish the baseline situation (year zero). This should be a measurement in terms of traffic volumes, crashes per road type, and therefore risk factors per road type. A site inspection is required to collect this data (see Diagnosing the Contributing Factors to Crashes) for further detail regarding site inspections). The site inspection should consider all road users, the surrounding road network, topography, local amenities and activity centres, local weather conditions, previous road safety reviews, and any complaints received from the community regarding the site.

- Determine the future situation without any implemented measures (known as the ‘Do Nothing’ or ‘Do Minimum’ scenario). This should consider current circumstances and conditions and should account for traffic growth.

- Determine the future situation under each of the applied road safety schemes. This should include a wide variety of alternatives and an estimate of the effects per road type. It should consider each road user group for each of the schemes. Each scheme should be measured in terms of its impact on the number of crashes and crash severity through a crash prediction model (see AASHTO, 2025).

- Perform cost-benefit analysis for each possible road safety scheme. This is done by assigning a monetary value to the safety impacts of each scheme and allows for the schemes to be ranked in order of effectiveness.

- Optimize the plans of each scheme. This is done to achieve the optimal safety effect and best cost- benefit rating.

A detailed final report should be completed at the end of the road safety impact assessment. This should include such details as:

- The definition of the problem and project objectives (both in terms of infrastructure changes and road safety).

- How the road network will be affected by the proposed scheme.

- Analysis of the existing road safety problems on the current network.

- Analysis of crash history in the area.

- Consideration of the consequences of the ‘Do Minimum’ approach.

- A detailed description of each alternative road scheme.

- Comparison of each scheme, including cost-benefit analysis from a safety perspective compared to the ‘Do Minimum’ approach. This is the main element of the report and an assessment of the effectiveness of each scheme must be made in terms of predicted crashes.

- Ranking of the scheme options, ordered in terms of the road safety savings.

During a road safety impact assessment, it is important to ask certain questions. Are the road safety policy targets realistic or ambitious? Are there other cost-effective schemes that have not been considered yet? Are the selected schemes suitable, not just in terms of safety, but in terms of other issues such as impacts on the environment, or accessibility and connectivity for all road users? Are there any associated social issues, such as a lack of support from the community?

It is important to note that a road safety impact assessment does not replace a road safety audit; it is merely a preliminary step towards selecting the most beneficial design for a project. Road safety audits are essential for ensuring all hazards are identified throughout the design and construction processes, which will be discussed in detail in Road Safety Audit.

Part C of the Highway Safety Manual (AASHTO, 2025) provides information on crash prediction models for different road types, including rural two-lane, two-way roads, rural multi-lane highways, and urban and suburban arterials. It covers both undivided and divided roadway segments, and intersections with various control devices and numbers of legs. This can be used to predict the expected average crash frequency, which is determined based on traffic volumes and roadway characteristics. Based on the foundations and framework set by the Highway Safety Manual, other models have also been developed, such as the European PRACT models, which can be used for different infrastructure characteristics typical of European countries (Karathodorou et al., 2016).

BOX 10.1: THE HIGHWAY SAFETY MANUAL AND ASSOCIATED TOOLS

The Highway Safety Manual (AASHTO, 2025) was developed to help embed safety considerations in decision-making relating to roadway planning, design, operations, and maintenance. A number of tools have been developed to support these objectives, including Safety Analyst (discussed in Section 9.4 Management Tools), the CMF Clearinghouse (see Section 11.3 Intervention Option and Selection), and the Interactive Highway Safety Design Model (IHSDM).

The IHSDM is a suite of software for evaluating the safety and operational effects of geometric design decisions (from design plans). These are advanced safety analysis and prediction tools and considered ‘best practice’ by many safety professionals (see e.g. Schermers et al., 2011).

The development of these tools is based on a wide and robust range of research including on crash prediction models and crash modification factors (CMFs) undertaken mainly in North America over the last 15 to 20 years. IHSDM is particularly useful for selecting the safest option from a list of possible options and for understanding the safety trade-off that might result from a lower standard design that may be required due to site constraints or construction cost savings. This tool uses crash prediction models and CMFs to predict crash occurrence. The models and CMFs are continually being refined as new research becomes available. IHSDM has calibration procedures that allow it to be customised for each US state or for other jurisdictions. Testing of these procedures has occurred in some European countries as well as Australasia.

ROAD SAFETY AUDIT

A road safety audit is defined as a formal and independent technical check of a road scheme design and construction, to identify any unsafe features or potential hazards and to provide recommendations for rectifying them during all stages, from planning to early operation (PIARC, 2023; ETSC, 1997; TII, 2017; Highways England, 2019).

The main aim of a road safety audit is to identify and address any road safety issues. A road safety audit is not a check against design standards, but a hazard detection tool. A road scheme, when audited, should be analysed under all operating conditions and consider all road users (motorized and non-motorized).

Road safety audit is a cost-effective measure for identifying and addressing likely safety issues. The earlier the audit is undertaken, the greater the benefit, as adjusting design plans can be a cheaper option than retrofitting safety features once a scheme has been built. Several studies have documented the benefits of conducting road safety audits. As an example, Macaulay and McInerney (2002) estimated that a sample of design stage audits had a benefit cost ratio (BCR) of between 3:1 and 242:1 by implementing all the recommendations from individual audits. In addition, 75% of recommendations had a BCR greater than 10, and 90% of recommendations had a BCR greater than 1.

Road safety audits (as well as other proactive methods) are very important for LMICs, as they provide an opportunity to develop a culture of road safety amongst those responsible for the planning and delivery of road infrastructure. On this basis alone there is a very strong case for the development of a formalised process for road safety audits for all major infrastructure projects. The Kazakhstan case study provides an example of some of the added benefits that can be gained from large road safety audit projects in LMICs.

CASE STUDY - Kazakhstan: Road safety audit of 1,062 km of road

There was a need to establish safe and efficient transport corridors along the Western Europe to Western China International Transit Corridor. Relevant standards including road design safety standards and available data about road crashes were reviewed. The designs of sections not yet under construction or finalized were audited and other sections in the stages of pre- and post-traffic opening inspected. This process involved training of 16 participants from different institutions related to the Ministries of Transport and of Internal Affairs. PIARC guidance on road safety audit and safety inspection was used as the basis for this work, but was tailored for local use. Read more

Many international guides exist on how to conduct road safety audits. PIARC developed a Road Safety Audit Guide (PIARC, 2023) that provides a comprehensive step-by-step procedure on how to conduct a road safety audit, as well as providing detailed individual checklists for motorways, inter-urban and urban main roads at each of the design stages (feasibility study, preliminary design, detailed design, and pre- and post- traffic opening). The guide also provides checklists for road safety audit, which are discussed in more detail below. Other useful guides include the FHWA Road Safety Audit Guidelines (FHWA, 2006), the Austroads Guide on Road Safety Audit (Austroads, 2022) and the CAREC Road Safety Audit manual (ADB, 2018). The African Development Bank (AfDB, 2014b) has released guidance that is specifically intended for use in the LMICs.

As identified in Section Examples of Infrastructure Policies, Standards and Guidelines in Section 9.3 Policies, Standards and Guidelines, the EU Directive on road infrastructure safety management states that road safety audit be conducted on all infrastructure projects on the Trans-European Transport Network (Motorways and Primary Roads) and other EU-funded roads, and suggests that these should also occur for all national roads. The Directive also states that such audits should be conducted at the draft design, detailed design, pre-opening and early operation stages. This is also the approach of the United Kingdom (Highways England, 2019). Many countries, on the other hand, provide for additional audit stages at the feasibility stage (e.g. Australia, New Zealand, Ireland, Qatar, South Africa) and/or during works (e.g. USA, Qatar, South Africa).

Austroads (2022) also introduces thematic audits that consider specific road user groups (e.g., pedestrians, cyclists, heavy vehicles) and their unique needs and interactions with infrastructure. These audits often require specific methods (e.g., cycling audits conducted from a bicycle) and may benefit from involving representatives of relevant user groups (e.g., elderly, disabled).

The PIARC (2023) guide identifies three parts in the auditing process – commissioning, undertaking and completion. Details on each of these stages are provided in that document, together with the roles and responsibilities of the parties involved.

The selection of an appropriately skilled audit team is an important part of the commissioning phase of the audit process. It is essential that the team is independent of the design team, freeing them from constraints imposed during the development phase and allowing them to examine the project with ‘fresh eyes’. The size and make-up of the team will vary depending on the size and complexity of the project and the stage of audit being undertaken. It is important that the team members, and particularly the team leader, have the necessary training to undertake a road safety audit. Auditors typically require strong expertise in road engineering and road safety investigations. For complex projects, supplementing the team with specialists in relevant areas such as transportation and land-use planning, traffic engineering (operations and maintenance), vehicle dynamics, human factors, etc., may be appropriate.

Many countries have developed formal training requirements (sometimes referred to within national guidance on road safety audit) and registers of appropriately qualified auditors. For smaller projects, it may be possible for a single auditor to complete a ‘road safety check’, and although this is not ideal, it is certainly preferable to no audit at all.

Audits rely on existing design standards, but they must go beyond a simple verification of compliance with standards, which may be unsatisfactory in some circumstances:

‘‘Applying standards and practices without considering prevailing circumstances is no substitute for judgement, and brings no assurance of an acceptable end product. Equally, designs prepared without referring to generally accepted standards and practices are not likely to serve the travelling public as intended. Designs based on a combination of sound professional judgment, applicable standards and current practices will generate the most effective highway…’’ (Professional Engineers of Ontario, 1997)

The availability and development of suitably skilled road safety auditors is an important challenge for those in the LMCIs. Capacity can be increased in the short term by training of key staff (either within their own country, or through established courses in HICs). In the medium term it is desirable to establish capacity within a country to train auditors. This will typically require some form of longer term ‘train the trainer’ approach, whereby a small number of experts are provided with advanced training and on-going support. These experts then develop skills through experience to a point where they are in a position to train others.

Many countries have developed checklists for conducting road safety audits. These checklists provide examples and reminders of issues that should be assessed by audit teams during their assessment. They are useful to ensure that key issues are considered, but it also needs to be recognised that every situation differs, and therefore checklists should typically be used as guides only and as a way of ensuring that no aspect has been missed. They do not form part of any formal audit report. This is because there may be other issues identified during an audit that were not anticipated by the existing checklist. Different checklists have been developed for different stages of the road safety audit process, or for thematic audits.

One criticism of road safety audits in the past is that the recommendations from the audit are not implemented. It is therefore critical that there be a process to complete the audit, including a formal response to the report. This should document a response to each of the actions recommended; and in cases where recommendations have not been accepted, the reasons for this and any other mitigating strategy that will be undertaken to help minimise risk should be stated. This written response to the audit report should become part of the project documentation.

Harwood et al. (2014) suggested that audit could be a costly method for identifying interventions, and that there is potential to miss interventions that could be added that are cost-effective ways to improve safety. Also, economic assessment of interventions is typically not included unless conducted as an addition to the normal audit process. On the positive side, they suggest that audit is a useful way to identify safety features that are missing or in poor condition, and that they are a good way to bring together expert staff to review safety. They also identified advantages in conducting field reviews (i.e. site inspections), a process not always undertaken in other methods of risk assessment. However, benefits of road project audits have been clearly demonstrated in studies. Typically, audits account for less than 4% of the total design costs, but they produce significant returns in terms of crash savings and cost-effectiveness (Austroads, 2022).

It is important to note that the road safety audit process has been around for many years. It was first established in the late 1980s, with documentation developed in many countries from the 1990s. However, there has been increasing adjustment of the road safety audit process to include Safe System concepts as part of auditors’ ongoing training and updates to processes. In some countries, the focus is shifting to better capture issues related to eliminating death and serious injury, although this has always been an integral part of the audit process. The focus remains primarily on road-based deficiencies and the solutions are generally aimed at improving the road environment. In many situations, this approach may be adequate; however, to take a Safe System-based approach, some jurisdictions have developed assessment frameworks that could be considered Safe System audits. These differ to traditional audits because they focus attention on the reduction of fatal and serious casualties and/or take a more holistic view of problems (and solutions) involving each of the Safe System pillars (e.g. safe user issues such as fatigue, potential for speed related crashes). The Australia case study provides one such example.

CASE STUDY - Australia: Application of the safe system approach through safe system audit/review

In 2007, the Commissioner of Main Roads Western Australia directed that the road safety aspiration for a major road project would be zero deaths within the first five years of operation and the minimum condition of satisfaction would be a 10% reduction compared with best practice for the context of the road (i.e. a 10% improvement over existing best practice design). As the best design standards of the day were to be complied with and thorough road safety audit/review processes were to be applied (as per normal practice), it was unclear how road safety could be further improved. A new approach that focused attention on the fatal and serious injury crash risks was developed and applied. This provided a structured approach to the assessment of the project against Safe System objectives. Read more

A further example was developed by the Department of Planning, Transport, and Infrastructure (DPTI) in South Australia. This involved a full Safe System assessment for a major project and was used as part of a successful business case to government to secure funding. The approach differed from a typical audit because it assessed vehicle and behavioural issues as well as the typical infrastructure issues.

Interestingly, some of the vehicle and behavioural issues identified were able to be addressed through infrastructure changes (also see the discussion in Section 8.2 Designing Infrastructure to Encourage Behaviour).

In a recent development, quantified audits have been undertaken to determine the impact of new design. Changes can be made to this design and likely safety improvements determined. An example of this approach is provided in Section 9.4 Management Tools.

The international Road Assessment Programme (iRAP) has developed a technique to star rate design plans (SR4D). Details on this approach can be found in the case study in Section 9.4 Management Tools.

PEDESTRIAN AUDITS

Recognizing the critical need to improve pedestrian infrastructure quality and safety, PIARC developed the Walkability Checklist and the Checklist for Quality and Safety Inspections of Pedestrian Infrastructure. Both of these checklists are discussed in detail in the following article: Pedestrian Audits - A Checklist for Safety and Quality Inspection of Pedestrian Infrastructure (Schmitt & Gerlach, 2018). The intent of these checklists is to find optimal solutions for walking and sojourning. The checklists incorporated Rumar's order of problems approach, where these orders of requirements are defined in three levels (Rumar, 2002). The first level requirements are those visible, tangible and concrete requirements concerning the physical environment, pedestrians, vehicles and the behaviours of other road users. The second order requirements concern the tactical level facilities and services, such as how the network is designed and operates, the traffic rules, and enforcement, management of the system and other like elements. The third order requirements allow the first and second order requirements to be met. These include land use characteristics, mode split, pedestrian quality, the culture, and other aspects that relate to the ease and desire to walk. The Walkability Checklist considers the design of the roadside environment as first order requirements, with traffic rules and traffic flow as second order requirements. The checklist recognise that requirements go beyond objects, facilities and services to consider context, process and procedures. The Walkability Checklist reviews pedestrian quality elements and whether general walkability requirements are fulfilled. The Checklist also helps define the stakeholders' responsibilities for the walkability requirements under consideration and what procedures need to be applied.

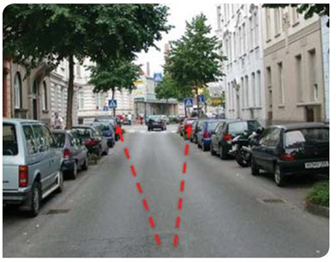

The Checklist for Quality and Safety Inspections of Pedestrian Infrastructures (CQSI) builds upon the Pedestrian Quality Needs (PQN) Inspection process. In general, the PQN is a systemic onsite expert review of the walking condition requirements through identification of hazardous conditions, faults and deficiencies that reduce pedestrian demand, conditions, comfort and safety. Because the PQN considers the quality and safety concerns of the pedestrian infrastructure, the CQSI was developed as the next step to the PQN. The checklist is intended to identify all of the relevant deficiencies of the pedestrian infrastructure. The photo below provides an example of a pedestrian deficiency that might be identified through the pedestrian audit process.

ROAD SAFETY INSPECTION

The PIARC Road Safety Inspection Guideline for Safety Checks of Existing Roads (2012a) defines a road safety inspection (RSI) as a systematic, on-site review of an existing road with the aim of identifying hazardous conditions, faults and deficiencies that may lead to serious crash outcomes. An RSI must be carried out by an independent, qualified individual or team with the relevant experience, and is specific to existing roads, not those under construction. It is also a proactive method in that the prevention of crashes is achieved through identification of potential safety issues, rather than responding to recorded crashes in a crash location investigation.

Road safety inspections are useful as they can:

- Complement high risk location treatments.

- Identify issues with current maintenance procedures.

- Identify locations for mass action treatments (i.e. hazardous features across a whole road network).

- Allow for proactive treatment of potential crash locations (before crashes occur).

- Check for consistency of road features.

- Check for adequacy of traffic management features.

The PIARC (2012a) guide identifies the following topics as necessary to be covered during an RSI, as well as some of the questions a safety check team should be considering during an investigation:

- Road function – is the road/speed limit appropriate for the role it plays in the network?

- Cross-section – is the road wide enough? Are the line markings sufficient? Are the road surface conditions adequate?

- Alignment – how do the horizontal and vertical alignments interact? Are sight distances adequate?

- Intersections – is the intersection layout and design appropriate for the volume of traffic passing through and the turning movements?

- Public and private services – are there sufficient deceleration/acceleration lengths leading up to and away from service and rest areas? Are the parking and loading facilities for public transport sufficient?

- Vulnerable road user needs – have pedestrian, cyclist, scooter/moped and motorbike rider needs been accounted for?

- Traffic signing, line marking and lighting – are traffic signs and line markings appropriate and clear? Is the site well lit?

- Roadside features and passive safety installations – are there roadside obstacles present that may pose safety issues?

There are four main steps to a road safety inspection on an existing road.

- Desk study.

- On-site field study.

- Road safety report.

- Implementation of remedial measures.

An on-site field study component of RSI has evolved in recent years. Survey vehicles can be equipped with automated devices to measure and record design and road management elements (e.g. horizontal and vertical alignment, super-elevation, pavement surface condition, presence of roadside hazards, road inventory etc.). This information can be assessed to detect issues with routes, such as anomalies in curvature (e.g. unexpected severe curves), slippery road surface or presence of roadside hazards. New technologies for road surveys have evolved significantly in recent years with the progress of AI, focusing on enhancing accuracy, efficiency, and cost-effectiveness. Some of the most popular are: LiDAR (Light Detection and Ranging), Drones (Unmanned Aerial Vehicles - UAVs), Mobile Mapping Systems (MMS), etc.

Further details on this data collection can be found in Section 5.4 Non-Crash Data and Recording Systems.

A road safety inspection of an existing road aims to detect features that may lead to future crashes, and past crash information is not always a good indicator of this. Crash investigation and prevention programmes look at features that contribute to the occurrence and severity of crashes that have already happened. An RSI does not require crash data, but it can be a useful tool in terms of providing guidance towards prioritising which roads should be inspected. For instance, if the road authority only has enough funding to inspect a select number of roads, priority can be given to roads with a high number of crashes per kilometre, or crashes per traffic volume. More detail on prioritisation of policies, projects and treatments can be found in Section 11.4 Priority Ranking Methods and Economic Assessment. Road safety inspections can be a useful complement to reactive approaches, such as high crash location investigations.

Sometimes RSI is undertaken on specific themes, for instance to identify issues relating to pedestrians or bicycles. This approach has been developed even further in France, where a method involving a specially equipped bicycle has been established to assess the bicycle network (Cerema, 2010). Further information on this approach can be found following this link.

An RSI is not the same as a routine maintenance check, where issues such as vegetation, road surface inconsistencies and poor quality signage are reviewed and remedied. However, an RSI can identify safety issues that are a result of poor maintenance, such as poor signing, line marking or visibility issues.

Road safety inspections can lead to:

- The identification of inadequate road management practices.

- The initiation of new works programmes.

- Changes in prioritisation of existing programmes.

- Changes to maintenance procedures to meet road user needs.

Human factors are a crucial part of identifying hazards at a site. Further discussion on this issue can be found in Chapter 8. Design for Road User Characteristics and Compliance.

Road safety inspections can be performed on the whole road network or on specific locations that are regarded as being the greatest risk. This is dependent on the road authority. It is important to note that road safety inspections of existing sites can result in a huge number of identified hazards and road safety issues. Under these circumstances, it is not economically viable to attend to all the issues listed. There is also little benefit to conducting an RSI on a site if the resources will not allow the majority of hazards to be addressed following the inspection. Sometimes it is more beneficial to invest in a maintenance programme to address a number of issues rather than conduct a formal RSI.

The PIARC Road Safety Inspection Guideline for Safety Checks of Existing Roads (2012a) provides a number of helpful checklists for different road types to ensure that each investigation of a site considers all the necessary elements. The checklists are similar in nature to those used for road safety audit. The guide also provides examples of appropriate RSI reports for both inter-urban and urban main roads. The African Development Bank (2014c) has released guidance on Road Safety Inspection that is specifically intended for use in LMCIs.

ROAD ASSESSMENT FOR SAFETY INFRASTRUCTURE

The proactive approach has been extended with a method that takes a quantified approach to the inspection of existing roads and road designs. Although several approaches exist, the most commonly applied is the Road Assessment Programme (RAP). Different RAP programmes exist in different regions, including usRAP, AusRAP, KiwiRAP and ChinaRAP. These all fall under the global banner of iRAP (the International Road Assessment Programme). PIARC (2012b) notes that the iRAP approach is of great benefit where crash data is unavailable, or coverage is limited.

RAPs take the concept of road safety audit and inspection a step further by estimating the risk (based on likelihood and severity) for different road sections based on road and roadside characteristics. A number of road elements are collected (e.g. through video and subsequent desk-based assessment; also see Section 5.4 Non-Crash data and Recoding Systems). Based on research conducted over many years, a lot is known about each of these variables, and the level of risk each produces. As an example, a straight section of road is safer than a road with a severe bend, and this risk level can be quantified. Each of the variables is quantified and an algorithm determines the risk of a fatal or serious injury for each segment of road (iRAP uses 100 m segments).

Such an assessment can be used to identify the highest risk and lowest risk segments of a network or road. A five-star rating system is used, with a one-star road providing the poorest road infrastructure, while on a five-star road the likelihood of a crash occurring and the severity of those that do occur is lowest. This information can also be colour-coded to provide a quick visual indication of road infrastructure safety. The process also allows separate star ratings for different types of road user (i.e. the vehicle occupant, pedestrian, bicyclist and motorcyclist).

The information can also be used to identify safety improvements that may be implemented, both at specific locations and across a whole network. Calculations can be updated to determine the likely safety benefit from such improvements. With knowledge of treatment costs and their benefit, as well as estimates of fatal and serious crash outcomes for a road network, an economic calculation can be undertaken to determine the most beneficial group of treatments to be applied to a road network or at a location. The software for this analysis is available online and is provided free to road authorities to use. Further details on this can be found in Chapter 11. Intervention Selection and Identification while a detailed description of the iRAP approach can be found at www.irap.org.

Reflecting the strong empirical basis behind the iRAP model, there is a strong linkage between the Star Rating of a road and the actual safety performance. An analysis performed by McInerney and Fletcher (2013) based on Star Ratings and crash cost (the average vehicle occupant fatal and serious injury crash costs per vehicle kilometre travelled) for almost 1,700 km of highway provides an example of this relationship. For each reduction in star rating (i.e. improvement in safety), the crash cost roughly halved. When moving from 1 star to 2, the crash cost reduced by 40%; from 2 star to 3 costs reduced by 61%; and from 3 star to 4 costs reduced by 44%.

Harwood et al. (2014) assessed the usRAP tools and compared this approach to other methods of assessing risk. They suggested that the approach was the most robust and quantitative in selecting interventions to improve safety, and that the recommendations were accompanied by economic assessment often missing in other methods. However, the approach was also identified as being quite labour intensive, with reliance on collecting roadway data and the coding of this data by skilled staff. However, they also suggested that this could be accomplished in a reasonably efficient manner. The consideration of risks associated with specific road user groups (motorcyclists, pedestrians, bicyclists as well as vehicle occupants) was also seen as an advantage.

A similar approach to iRAP was adopted in South Africa, with the use of Net Safe.

CASE STUDY - South Africa: Identification of hazardous locations using Net Safe

Crash statistics in South Africa are of poor quality. This makes it difficult to identify hazardous locations and the causes of crashes. The solution involved the identification of potential hazardous locations on roads based on the existing road elements. South African National Roads Agency Ltd (SANRAL) developed a Road Safety Management System (RSMS) that outlines a holistic approach to road safety on their approximately 20 000 km of roads. An element of the RSMS was the development of the Netsafe algorithm. Read more

CASE STUDY - South Africa: City of Tshwane: Implementing Community Based Road Safety Master Plans

The City of Tshwane is a city in transition and has a mix of established and historically disadvantaged areas. Fatality rates in these areas were high and the communities were discontented about the road safety situation. The case study covers a process that was developed in the City of Tshwane to develop and implement Road Safety Master Plans, with input from communities where crash-data is not available and road deaths are prevalent. It entails a process that was developed to also integrate engineering, enforcement and education. Read more

CRASH PREDICTION MODELS

Over the last two decades, several researchers in Europe and worldwide, have examined the safety effects of various elements of the road infrastructure in an attempt to quantitatively estimate or ’predict’ crash frequency (number of crashes per year) and crash severity (level of injury due to crashes). As a result of this research, a large amount of relevant knowledge has been developed, as well as various methodologies and techniques to estimate future crash frequency and severity and to identify and evaluate options to reduce them. These methodologies are commonly known as Crash Prediction Models, and they essentially are the statistical - mathematical models behind most road assessment methodologies based on design characteristics of roads.

These models estimate the number of crashes based on functions of independent variables. The following simple model form is often used:

With this simple form, the influence that geometric features have on crash occurrence is taken into account by establishing a distinct reference population for each group of sites having similar features and by developing a model for each of these populations. For example, a model could be developed for rural cross intersections, another model for rural T intersections, and so on.

Alternatively, the effect of key geometric road features could also be assessed by developing more complex models that include not only traffic variables, but also geometric variables.

Two basic groups of these more complex models are present in international literature and road safety practice, namely the US Highway Safety Manual (HSM) predictive method (AASHTO, 2025) and stand-alone multivariate Accident Prediction Models correlating crash frequency to traffic and road geometric characteristics, developed using specific datasets by individual researchers (and thus applicable to circumstances similar to the ones they were developed from). Based on the foundations and framework set by the Highway Safety Manual, other models have also been developed, such as the European PRACT models (Karathodorou et al., 2016).

The estimate of the expected average crash frequency relies upon regression models developed from observed crash data for a number of individual sites. Different regression models, called base Safety Performance Functions (SPFs) have been developed for specific facility types (e.g. undivided segments of rural two-lane two-way roads, divided segments of urban and suburban arterials, three-leg intersections with ‘STOP’ control in rural multilane highways etc.) and ‘base conditions’, that are the specific geometric design and traffic control features of a ‘base’ site.

The general form of the predictive models in HSM, for a given type of site, is shown in the following equation:

where:

Npredicted = predicted average crash frequency for a specific year.

Nspf = predicted average crash frequency determined for the base conditions of the Safety Performance Function (SPF).

CMF1 .... CMFy = crash modification factors.

C = calibration factor to adjust the SPF for local conditions related to the network where the model is to be applied

The procedure and an example of application is shown in Appendix 10.2 (Crash Prediction Models).

Advantage

- Accuracy.

Disadvantages

- Complexity.

- Does not consider the random nature of crashes.

IDENTIFICATION – A BROADER PERSPECTIVE

Most road authorities allocate a share of their operating budget to the improvement of high-risk locations and the correction of hazardous road elements. However, due to other requirements related to the development and operation of a road network, funding for such specific safety actions is generally quite limited. Nevertheless, most actions taken by a road authority have a safety impact, whether they are initiated for safety reasons or not. If these impacts were properly assessed, crashes could be avoided, often at little or no cost. The implementation of RSAs has marked a major improvement in that direction, but more can be accomplished.

The following paragraphs describe how decisions are currently made by most road administrations (Decision-making process) and then propose general solutions for better incorporating safety concerns in current practices (How to broaden the safety perspective).

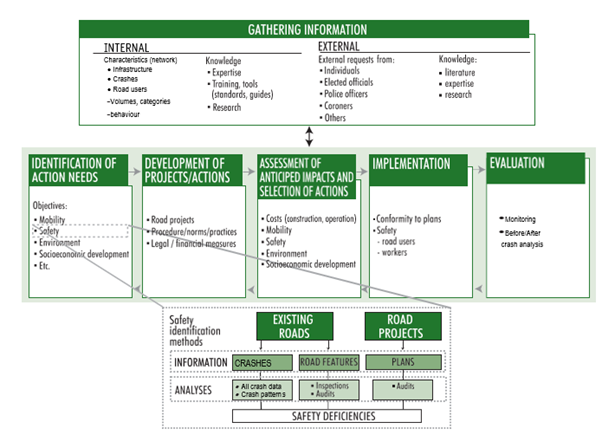

DECISION-MAKING PROCESS

Broadly stated, a road authority’s mission is to satisfy the mobility needs of people and goods and to support socio-economic development, while ensuring that the safety and environmental impacts of the road network are minimized.

To accomplish this mission, the following tasks need to be completed:

- Gather information.

- Identify action needs.

- Develop projects.

- Assess anticipated impacts and select actions.

- Implement selected actions and evaluate their consequences.

GATHER INFORMATION

In order to identify the most pressing action needs, a road authority uses various sources of information. First and most important, a reliable information system that accurately describes a road network’s features must be established (Chapter 5. Effective Management and Use of Safety Data). Other useful sources of information include:

- Employees’ knowledge, experience, and expertise.

- External knowledge (literature, experts).

- Requests from road users, local population, police officers, etc.

IDENTIFY ACTION NEEDS

Based on this information, the performance of a road network is assessed in accordance with the various organizational objectives, such as mobility, road infrastructure quality, environment, safety, and so on. Several performance indicators have been developed to assist in this task (e.g. Table 10.6). Methods for assessing the safety performance of a road network have been described in detail earlier in this chapter.

DEVELOP PROJECTS

Based on the identified needs, various projects are then developed. They may consist of:

- Actions aimed at maintaining the integrity of the existing network (road resurfacing, trimming of the vegetation, pavement marking, etc.).

- Actions aimed at improving existing road features (installation of improved protection devices, change from a conventional intersection to a roundabout, etc.).

- Development of new roads.

- Changes to existing procedures/standards/practices: work-zone management procedures, geometric standards, maintenance practices, etc.

- Legal/financial incentives or deterrents (e.g. laws, funding, taxes).

ASSESS ANTICIPATED IMPACTS AND SELECT ACTIONS

Most of these measures and actions have an impact on more than one performance indicator (Table 10.9). For example, a road resurfacing project that improves surface quality is likely to lead to speed increases, with secondary impacts on safety, mobility, and vehicle emissions. These various impacts should be formally assessed.

Objective | Performance indicator |

Mobility |

|

Road surface condition |

|

Environment |

|

Safety |

|

IMPLEMENT AND EVALUATE

During construction, appropriate monitoring is required to ensure that the implementation conforms to proposed plans and does not lead to the introduction of new road hazards.

Evaluations should also be conducted after a project's completion in order to ensure that anticipated benefits have been achieved and to ascertain that adverse effects have not been introduced into the system. Results of these evaluations will also contribute to improve the efficiency of future actions.

A schematic representation of this decision-making process is shown on Figure 10.21 below.

HOW TO BROADEN THE SAFETY PERSPECTIVE

MORE SAFETY ASSESSMENTS

As defined previously, a road safety audit is a formal assessment of the safety performance of a road project or an existing road conducted by a team of independent experts. There is a need to expand the scope of these safety evaluations to include activities of a road authority that are not currently submitted to this type of evaluation but do have an impact on safety. These include:

- Road projects that are not audited.

- Procedures, programs and practices.

- Road-related laws and regulations (e.g. load and size limits).

- Incentives or deterrents (e.g. public transport funding).

BETTER USE OF AVAILABLE DATA, KNOWLEDGE AND TECHNOLOGY

Crash data, which are expensive to collect, are often underused, particularly in light of recent technological advances that significantly enhance the range of analyses that can be conducted with reasonable effort. The organization of this data and the development of user-friendly programs that facilitate the extraction and analysis of this information should become a priority.

Simple query programs should be made available to decision-makers, allowing them to make more informed decisions. More sophisticated programs should be developed for safety analysts, in order to help them using recent analysis methods and techniques. And finally, easy access to existing databases should be provided to researchers, allowing them to extract a maximum of information from these systems.

Software that facilitates the use of knowledge that has been gathered on road safety - partly through the use of available databases - should also be developed. A major effort in that regard is the American ‘Interactive Highway Safety Design Model (IHSDM)’ software, which is designed to help engineers take greater account of safety impacts when developing new road projects (see Box 10.3).

IMPROVED COMMUNICATION CHANNELS WITHIN ROAD AUTHORITIES

Engineers who develop new projects and safety experts often work in independent departments, with each having their own objectives and budgets. Designers typically believe that by following existing standards, they will necessarily develop safe projects, but experience shows that this is not necessarily the case. On the other hand, safety experts often work exclusively on the development of specific road safety programs (e.g. blackspot improvement program). The development of formal and informal communication channels between the various specialists in a transportation agency, and their partners is needed: working groups, ad hoc meetings, control points, joint seminars and social events should all be organized.